In today’s digital age, optical fiber networks are the backbone of high-speed internet, telecommunication, and data transfer. However, handling these delicate fibers comes with its own set of challenges. Manual fiber optic handling, while historically the norm, is increasingly being replaced by automation. Why? Because human error is costly, and automation promises to address the inefficiencies and risks that come with traditional methods. Let’s explore why automation is the key to revolutionizing fiber optic handling.

The Fragility of Optical Fiber

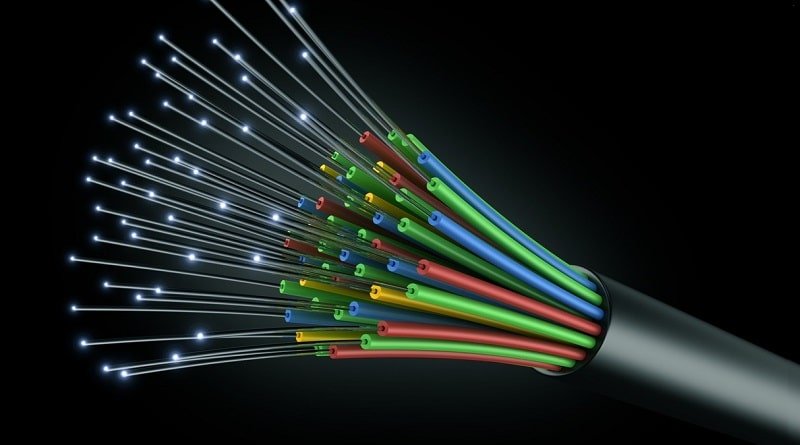

Optical fibers are incredibly thin—often no thicker than a human hair—and made of glass or plastic. While this makes them perfect for transmitting data at high speeds, it also makes them incredibly fragile. Even a slight bend, stress, or improper handling can cause them to break or lose signal quality. This fragility demands precise care during installation and maintenance.

The Problem with Manual Handling

Despite the delicate nature of optical fibers, the traditional method of handling them has been largely manual. However, this approach leads to a number of challenges:

- Human Error: Studies have shown that over 50% of fiber optic failures during installation are due to human error. Mistakes such as over-bending, misalignment during splicing, or incorrect fiber termination can have significant consequences.

- Performance Degradation: Improper handling can result in signal loss or complete fiber failure, which can damage network reliability.

In fact, a survey by the Fiber Optic Association found that 33% of fiber failures were caused by errors during manual installation.

The High Costs of Mistakes

While manual labor might seem cheaper initially, the reality is that errors during installation lead to costly repairs and downtime.

- Repair Costs: Fixing a damaged fiber optic cable can cost between $200 to $500 per fiber. This doesn’t include the time and labor required to fix the problem.

- Labor Costs: Fiber optic technicians earn an average of $50,000 per year in the U.S., and when labor is inefficient due to manual errors, the costs add up.

- Downtime: When a fiber failure occurs, businesses face downtime, which can lead to lost revenue and frustrated customers.

For example, the cost of network downtime can be as high as $5,600 per minute, according to Gartner. For large businesses, that’s millions of dollars lost in just a few hours of interruption.

The Business Impact of Fiber Failures

The consequences of fiber optic failures extend far beyond technical concerns—they can significantly impact a business’s bottom line. Service outages can affect:

- Revenue: As networks go down, businesses lose money. A Gartner report estimated that downtime costs large organizations about $5,600 per minute.

- Customer Satisfaction: A study by Microsoft revealed that 58% of customers would stop doing business with a company that experiences a prolonged outage. Customer trust and loyalty are at stake.

- Operational Efficiency: Businesses that depend on fiber optics for daily operations are vulnerable when those systems fail. The time spent fixing issues or dealing with disruptions is time lost, affecting productivity.

Additionally, brand reputation can suffer when customers take to social media to voice frustrations over service outages.

How Automation Fixes These Problems

Now that we understand the risks and costs associated with manual fiber handling, let’s explore how automation can help solve these issues.

1. Increased Accuracy and Precision

Automated systems are built with precision in mind. Unlike humans, machines don’t get tired or distracted. Automated systems ensure that:

- Fiber is handled carefully to avoid bends that exceed the minimum radius.

- Splicing is done with high accuracy to minimize signal loss.

- Termination is perfectly aligned for optimal signal transfer.

2. Lower Failure Rates

Automation significantly reduces human error. Where human handling might lead to a 25% failure rate, automated systems can reduce that number to as low as 5%. This improves the reliability of the fiber optic network and ensures fewer disruptions.

3. Faster Installation and Maintenance

Time is money. Automating fiber optic processes reduces installation times. For example, robotic splicing systems can complete the job 30% faster than manual methods, according to a study by Fujikura Ltd.

Faster installations mean quicker service rollout and the ability to scale fiber networks to meet growing demand without delays.

4. Cost Efficiency

Though automated systems come with an initial investment, they save money in the long run. Reduced labor costs, fewer errors, and faster project completion result in savings of 15%-20% over time. For businesses looking to maximize ROI, automation is a smart choice.

5. Enhanced Safety

Fiber optic handling poses risks to workers, including sharp glass splinters and repetitive strain injuries. Automation eliminates these dangers, providing a safer working environment and reducing worker injuries.

6. Scalability

With the growing demand for fiber optic infrastructure, companies need to scale quickly. Automation allows businesses to handle larger volumes of fiber installations and maintenance tasks without sacrificing quality or precision.

Case Study: Automated Splicing in Action

Splicing is one of the most crucial tasks in fiber optic installation, as it joins two fibers to ensure a continuous data stream. Manual splicing requires great skill and precision, but even small misalignments can cause significant signal loss.

Automated splicing systems have revolutionized this process. A 2019 study by Corning Inc. showed that automated splicing reduced splice loss from 0.3 dB (typical of manual splicing) to 0.1 dB, leading to better network performance. This improvement may seem small, but it makes a huge difference over long distances, where every decibel counts.

Conclusion: A Smarter, More Reliable Future

Manual fiber optic handling is no longer sufficient in today’s high-demand, high-precision world. Automation is the solution to reducing human error, speeding up installations, and improving reliability.

By embracing automated fiber optic handling, companies can:

- Ensure faster, more accurate installations.

- Avoid costly errors and downtime.

- Improve safety and scalability as fiber networks grow.

In a world where connectivity is essential to business success, automating fiber optic handling ensures a future-proof, reliable infrastructure that meets the needs of tomorrow’s digital world.