If you think a single speck of dust is harmless, think again—especially in the world of optical networking. A tiny contaminant, barely visible to the human eye, can cause catastrophic data loss, service disruptions, and costly downtime. It’s an invisible menace that keeps network engineers on edge.

But here’s the good news: while contamination is a nightmare, it’s not an unstoppable force. With the right technology, processes, and automation, we can fight back—and win.

Why Contamination is a Silent Killer

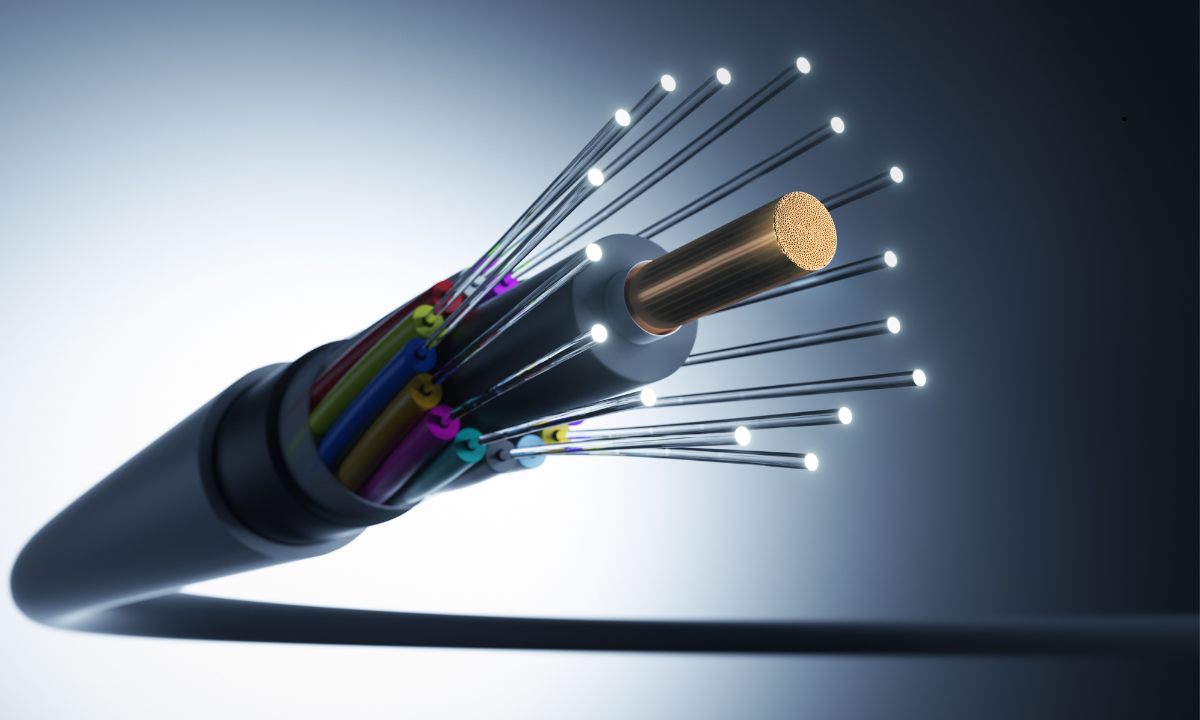

Fiber optic networks thrive on precision. Unlike electrical signals in copper cables, optical fibers rely on light passing through ultra-clean glass cores. Even microscopic debris, such as dust, oil, or residue from handling, can scatter or block light signals, leading to:

✅ Increased Signal Loss (Attenuation): Weakening or complete failure of data transmission.

✅ Reflection and Interference: Unstable connections causing network fluctuations.

✅ Permanent Connector Damage: Scratched end-faces leading to expensive repairs.

When you scale this problem across thousands (or millions) of fiber links in hyperscale data centers and telecom networks, the risk compounds exponentially.

Managing the Menace: How We Keep Optical Networks Clean

The battle against contamination isn’t fought with brute force—it’s a combination of vigilance, automation, and smart design. Here’s how the industry is staying ahead:

🔍 Inspection Before Connection

Before plugging in a fiber optic cable, professionals use fiber scopes with AI-powered image analysis to detect contaminants. If it’s not pristine, it doesn’t get connected—simple as that.

🌀 Contactless Cleaning Technologies

Traditional cleaning swabs are giving way to automated, non-contact solutions, using air-based or ultrasonic cleaning methods that eliminate particles without physical wear and tear.

🤖 Automation & Robotics

Why leave precision to human error? Automated fiber handling and cleaning robots ensure every connection meets cleanliness standards before it even reaches the network. This reduces risk and increases reliability at scale.

🚀 Smart Connectors & Self-Monitoring Networks

Newer fiber connectors come equipped with built-in contamination detection, alerting technicians before problems arise. AI-driven monitoring systems also analyze real-time performance data, flagging potential contamination issues before they escalate.

Final Thoughts: Fear the Dust, But Not the Future

Yes, contamination is scary—it’s an ever-present threat that can cripple the digital world. But thanks to cutting-edge innovations in fiber optics, the industry is turning fear into control. With automated cleaning, AI-driven inspections, and next-gen network intelligence, the future of fiber optics isn’t just clean—it’s bulletproof.

So the next time you stream a 4K video or make a lightning-fast trade on the stock market, remember: an invisible war is being fought in the background. And thanks to technology, we’re winning.